A history spanning over 50 years

A place where innovation meets sustainability.

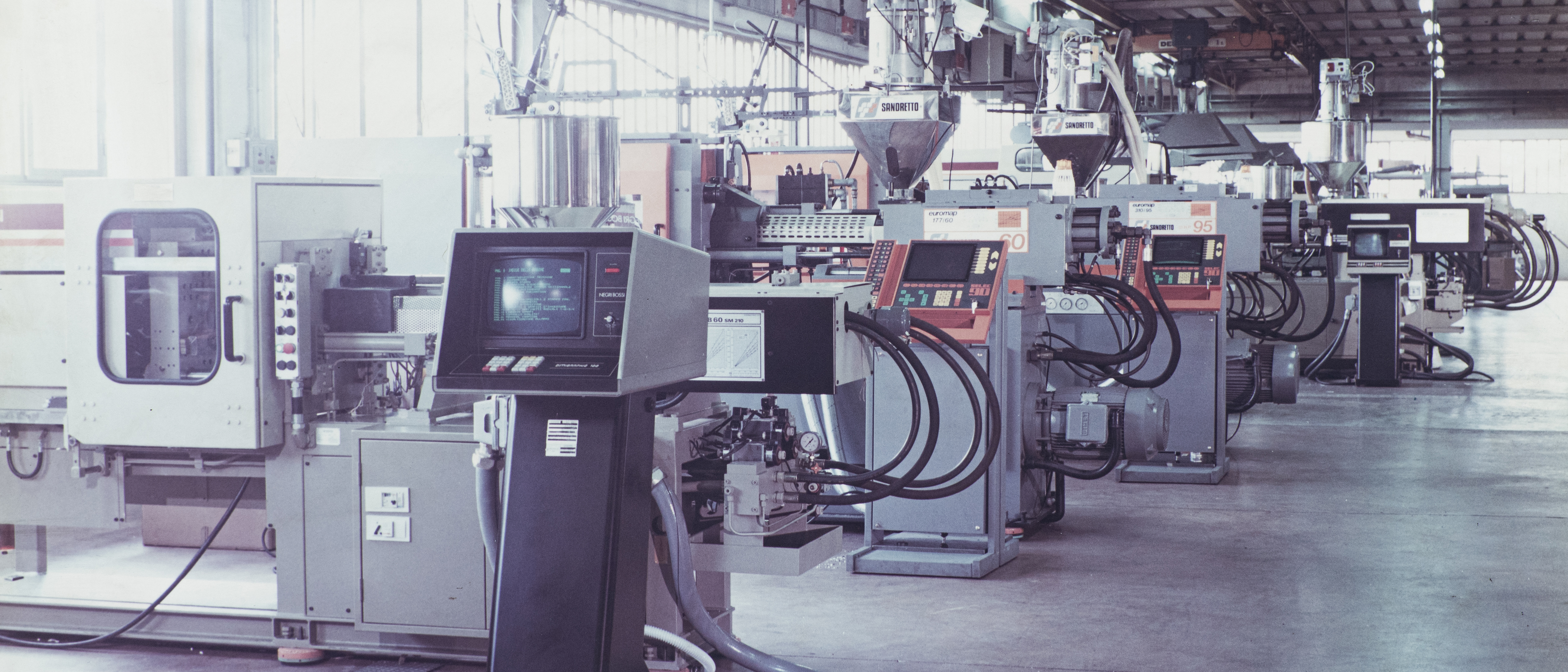

Born as a small injection mold production workshop in 1966, the Pezzutti Group is today equipped with over 160 injection presses from 10 to 2,000 tons, and has numerous technologies, including 2K and 3K injection, In Mold Labeling and In Mold decoration. The strong commitment to creating sustainable solutions is part of the company’s identity and is guaranteed by the ESG certification, for the evaluation of Environmental, Social and Governance impact performance. The use of 100% of our electricity consumption from renewable energy sources, a production process designed to eliminate environmental impact and specific know-how in the use of recycled plastic, together with Social and the Governance Responsibility, are part of the Values of the Pezzutti Group.

SustainabilityOur numbers

25.000 sqm:

production facilities with 4 factories

>300.00 pallets:

moved per year

18.000 sqm:

logistics facilities and warehouses

20.000 pallets:

of products finished in stock

>160 injection press:

machines with clamping force from 10 to 2000 tons

30.000 tons:

plastic materials converted every year

330 employees:

with 24x7 shifts

72% of production:

exported

>2.000 moulds:

in operation

Pezzutti factories and

logistics centers:

What do we do

Pezzutti Group is a strategic partner in the conception, co-design, mould building, development and production, including automation for mass production, of technical components and finished products, made of plastic materials and techno polymers. Our customers belong to the most diverse industrial sectors including large-scale retail trade, DIY, Home Furnishings and Office, Food Packaging Industry, Precision mechanical components, mechanical-textile, electrical and electronic, hydro-sanitary, air conditioning, Ventilation, hou- sehold appliances and the medical-dental sector.

Certificazioni

Quality management is peculiar to our production. Since 1998 we have respected the requirements of DIN ISO 9001 certification.

Our plant dedicated to the food industry complies with food safety management systems and is BRC certified. It also complies with and is certified according to the International Sustainability and Carbon Certification ( ISCC Plus ) standard. Energy management is guaranteed by DIN ISO 50001 certification: through the detailed register of all energy sources and energy-consuming equipment, together with the continuous verification of the energy efficiency of our machinery, equipment and processes, the energy management activities are certified implementation of energy saving measures, with the aim of exploiting all optimization potential.

Since 1966 we have been looking to

the future

Year 1966:

Pezzutti was founded in 1966 as a manufacturer of molds for thermoplastic resin injection and, immediately afterwards, a first factory with the first injection presses machines was added to the Tool Workshop, to mainly produce technical plastic components and consumer products.

Year 1970:

Complex technical components and conversion of parts from metal to plastic with the use of techno polymers, production began in the early 1970s, with the majority of molds designed and made internally. The Mold Workshop and the important Technical Department have always played a strategic role, with growing experiences that continue to remain an important value for Customers even today. Since the 1970s, the complete assembly service of sophisticated technical parts, made internally, has been offered to customers who request it.

Year 1990:

From the early 1990s the Food Packaging division was added in a new dedicated factory, mainly supplying European multinationals in the packaged ice cream and the fresh food and dairy industries. In these years the injection presses range from 40 to 950 tons of clamping force and the IML/IMD technologies are added.

Year 1999:

In 1999 Pezzutti began the first tests and production of items made from 100% recycled plastic, as a pioneer of the Circular Economy.

Year 2014:

In 2014 Pezzutti is certified “100% Green Energy”: a photovoltaic system producing > 1,000,000 KWH/year is added to complete the certification of use of 100% energy from Renewable Sources (Hydroelectric + Photovoltaic).

Year 2018:

In 2018, the fourth factory was built which began production based on the concept of Industry 4.0 and dedicated mainly to consumer and mass-produced products. New injection presses are added, bringing the machine park to 150 injection machines with powers from 10 to 2,000 tons. Production is supported by an important Quality Office for all the necessary checks and by a large group of engineering technicians capable of assisting customers in the development of customized solutions.

Year 2021:

In 2021 Pezzutti obtains the prestigious ESG (Environmental, Social and Governance) Certification: the standard that certifies corporate sustainability, expressed at an environmental, social and governance level, and which constitutes a valid control and compliance tool for the company.

1966

1970

1990

1999

2014

2018

2021